The city of the Gold Coast. My home. My grandfather was a steel fixer (labourer) who built some of these steel and concrete high rises in the 1960s and 1970s.

I live in one of the youngest cities of one of the youngest countries – the Gold Coast, in the state of Queensland, Australia. The resort city as we know it only really came into being in the 1950s and as a result, it is nearly impossible to find a standing structure that doesn’t date from the 20th century.

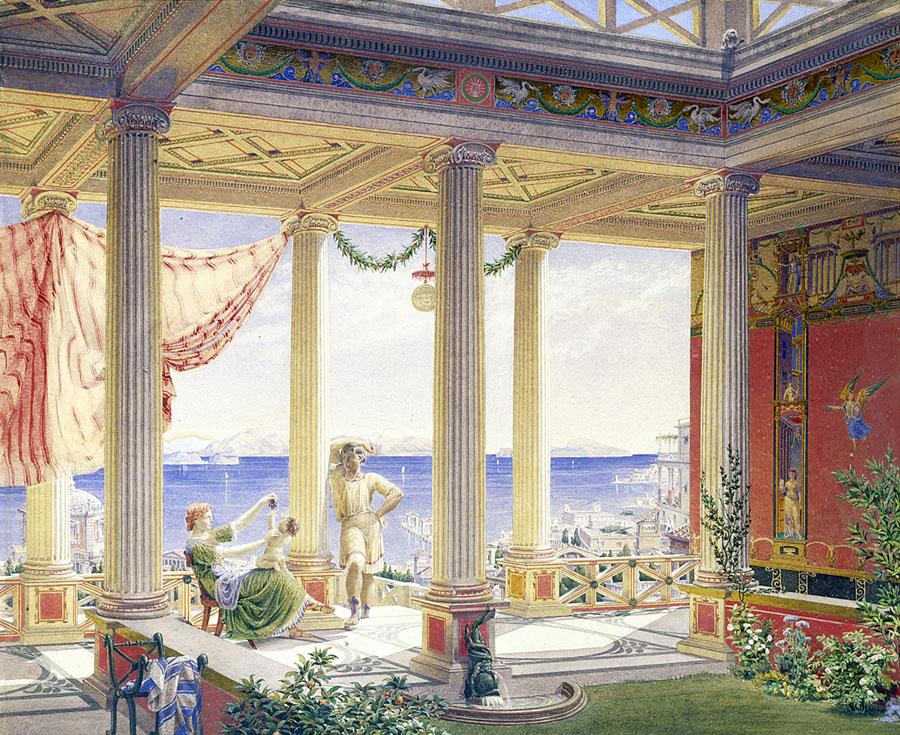

So, one can’t look at Ancient Rome without being in awe of buildings that have lasted more than a thousand years.

How did they do it?

They mastered the art of concrete.

Now, that might elicit one great big yawn today – after all concrete is everywhere, many of us might live in a concrete jungle. Concrete is so commonplace that it is easy to forget that the formula for it had been lost for more than 1000 years.

Even more remarkable is that engineers today are still studying the composition of Roman concrete to make improvements to today’s building material.

They have discovered that the ancient Roman formulation bonds better, is stronger, does not require reinforcing and is even more environmentally friendly!

The Romans’ recipe was essentially lime, volcanic ash and salt water. The interaction between these ingredients produces calcium aluminum silicate hydrate (CASH), which is the bonding material. The study also revealed that Roman concrete contains tobermorite, a material with a highly organized and very strong structure of molecules.

Researchers also found that the Roman process for creating concrete releases less carbon dioxide than today’s method. Portland cement requires an extreme amount of heat to produce, while the Romans used a naturally material, volcanic ash. We have experimented with using volcanic ash, and more commonly, fly ash, to replace Portland cement, but until now there was no way to know how strong this type of concrete would be.

Lynn, John; Smeaton’s Eddystone Lighthouse; Canterbury City Council Museums and Galleries; http://www.artuk.org/artworks/smeatons-eddystone-lighthouse-75968

For centuries following the fall of the Roman Empire, building material was limited to what could be quarried, nailed together or fired in a kiln. It wasn’t until 1756 that British civil engineer John Smeaton found a formula that worked after numerous experiments.

He used to be the Eddystone Lighthouse in Cornwall in 1793.

There were further improvements made to the formulation by another English inventor John Aspdin in 1824. He developed Portland cement which is still available today.

Even so, 19th century concrete wasn’t a patch on Roman concrete. The next leap in the modern version of the material came from Germany.

It was in Germany that the first systematic testing of concrete took place in 1836. The test measured the tensile and compressive strength of concrete. Another main ingredient of concrete is aggregate and includes sand, crushed stone, clay, gravel, slag and shale. Concrete that uses imbedded metal is called reinforced concrete or Ferroconcrete. It was Joseph Monier who first invented reinforced concrete in 1849. He was a Gardner who made flowerpots and tubs of reinforced concrete with the use of iron mesh. The reinforced concrete thus combined the tensile power of metal and the compression strength of concrete for tolerating heavy loads. He received a patent for this invention in the year 1867.

In 1886, the first rotary kiln was introduced in England that made constant production of cement. In 1891, George Bartholomew made the first concrete street in Ohio, USA. By 1920s, concrete found major usage in construction of roads and buildings. It was in 1936 that the first concrete dams Hoover and Grand Cooley were built.

Now the tallest structures man has ever known are made of reinforced concrete. It’s quite a feat, but it also comes with a downside. Steel rusts which means concrete spalling (concrete cancer) unless the concrete is maintained.

The stunning and incomparable oculus – the non-reinforced dome in Rome’s Pantheon.

Romans structures never had to worry about that because they never required reinforcing which is why today, the world’s largest non-reinforced concrete dome still remains the magnificent Pantheon built nearly two millennia ago in 125 AD.

[/vc_column_text][/vc_column][/vc_row][vc_row padding=”0″][vc_column width=”1/2″][vc_single_image image=”2419″ img_size=”full”][/vc_column][vc_column width=”1/2″][vc_column_text]Created for book lovers

Join Elizabeth’s Library Book Club today for free reads, exclusive excerpts, competitions and more![/vc_column_text][mk_button corner_style=”rounded” size=”medium” url=”http://box5218.temp.domains/~lizabga3/index.php/homepage/book-club/” target=”_blank” align=”center” margin_top=”6″ animation=”fade-in” bg_color=”#ff0202″]Join Now!

[/mk_button][/vc_column][/vc_row]